VAV Terminal Units

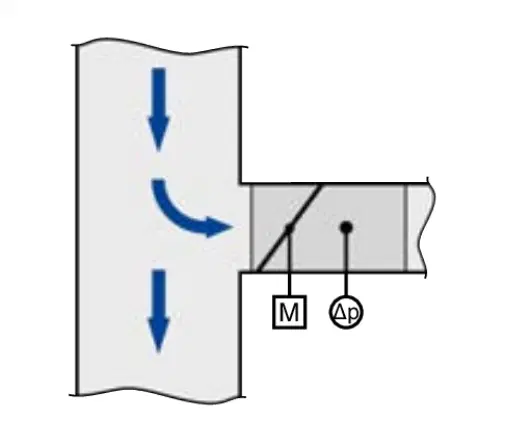

TVE

COMPACT SOLUTION FOR LOW AIRFLOW VELOCITIES

Circular air terminal units for use in variable air volume systems at low airflow velocities, even under unfavourable upstream conditions

- Effective pressure monitoring tubeless via damper blade

- Effective pressure transmission through effective pressure channel in shaft

- Terminals with protective cover – no junction boxes required

- Any direction of flow with dynamic transducer

- Suitable for airflow velocity of 0.5 – 13 m/s

- Compact dimensions for use in confined ceiling areas

- Plug-and-play solution in conjunction with X-AIRCONTROL room control

- Exact measurement even at low airflow velocities

- Any installation orientation, even with static transducers

- Closed blade air leakage to EN 1751, at least Class 3

- Casing air leakage to EN 1751, Class C

- Volume flow rate range 1:25

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Circular silencer, types CA, CS or CF, for the reduction of air-regenerated noise

- Hot water heat exchanger type WL and electric air heater type EL for reheating the airflow

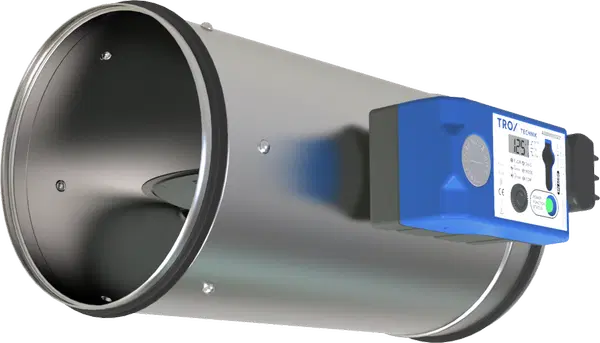

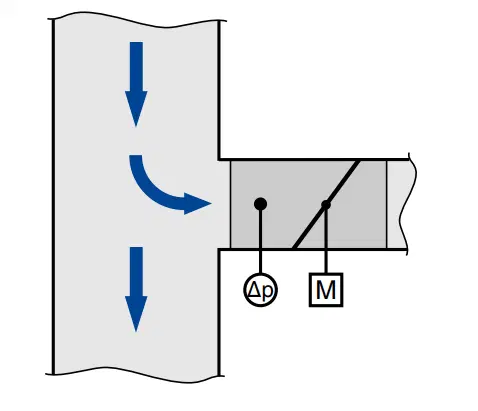

TVR

FOR VARIOUS STANDARD APPLICATIONS

- Circular air terminal units for standard applications in supply air or extract air systems with variable volume flow rates

- Suitable for the control of volume flow rate, room pressure or duct pressure

- Electronic control components for different applications (Easy, Compact, Universal, and LABCONTROL)

- High control accuracy even with upstream bend (R = 1D)

- Closed blade air leakage to EN 1751, up to class 4

- Casing air leakage to EN 1751, class C

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type CA, CS or CF for the reduction of air-regenerated noise

- Hot water heat exchanger Type WL and electric air heater Type EL for reheating the airflow

TVJ

FOR NORMAL AND HIGH VOLUME FLOW RATE RANGES

Rectangular air terminal units for standard applications in supply air or extract air systems with variable volume flow rates

- Suitable for volume flow rate ranges up to approx. 62,000 m³/h or 17,000 l/s

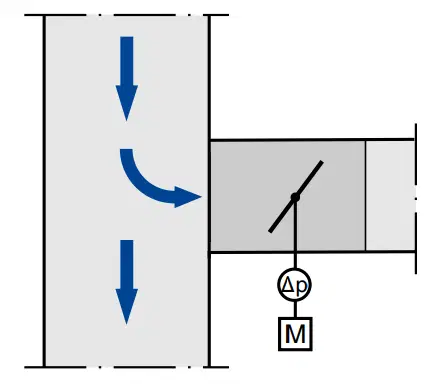

- Suitable for the control of volume flow rate, room pressure or duct pressure

- Electronic control components for different applications (Easy, Compact, Universal, and LABCONTROL)

- High control accuracy

- Closed blade air leakage to EN 1751, Class 1 (B + H ≥ 600 mm)

- Casing air leakage to EN 1751, class B

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TX for the reduction of air-regenerated noise

- Hot water heat exchanger Type WT for reheating the airflow

TVT

FOR NORMAL AND HIGH VOLUME FLOW RATE RANGES AND LOW-LEAKAGE SHUT-OFF

Rectangular air terminal units for standard applications in supply air or extract air systems with variable volume flow rates, suitable for low-leakage shut-off

- For volume flow rate ranges up to 28836 m³/h or 8010 l/s

- Suitable for the control of volume flow rate, room pressure or duct pressure

- Electronic control components for different applications (Easy, Compact, Universal, and LABCONTROL)

- High control accuracy

- Closed blade air leakage to EN 1751, class 3

- Casing air leakage to EN 1751, up to class C

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TX for the reduction of air-regenerated noise

- Hot water heat exchanger of Type WT for reheating the airflow

TZ-SILENZIO

FOR SUPPLY AIR SYSTEMS WITH DEMANDING ACOUSTIC REQUIREMENTS AND LOW AIRFLOW VELOCITIES

Rectangular VAV terminal units for the supply air control in buildings with variable air volume systems, demanding acoustic requirements and low airflow velocities

- Highly effective integral attenuator

- Optimised for airflow velocities of 0.7 – approx. 7 m/s

- High control accuracy, even in case of unfavourable upstream conditions

- Compact construction with rectangular connections on both ends

- Electronic control components for different applications (Easy, Compact, Universal, and LABCONTROL)

- Closed blade air leakage to EN 1751, Class 4

- Casing leakage to EN 1751, Class C

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TS for the reduction of air-regenerated noise

- Hot water heat exchanger of Type WT for reheating the airflow

TA-SILENZIO

FOR EXTRACT AIR SYSTEMS WITH DEMANDING ACOUSTIC REQUIREMENTS AND LOW AIRFLOW VELOCITIES

Rectangular VAV terminal units for the extract air control in buildings with variable air volume systems, demanding acoustic requirements and low airflow velocities

- Highly effective integral attenuator

- Optimised for airflow velocities of 0.7 – 7 m/s

- High control accuracy, even in case of unfavourable upstream conditions

- Compact construction with rectangular connections on both ends

- Electronic control components for different applications (Easy, Compact, Universal, and LABCONTROL)

- Closed blade air leakage to EN 1751, up to class 4

- Casing leakage to EN 1751, class C

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TS for the reduction of air-regenerated noise

TVZ

FOR SUPPLY AIR SYSTEMS WITH DEMANDING ACOUSTIC REQUIREMENTS

VAV terminal units for the supply air control in buildings with variable air volume systems and demanding acoustic requirements

- Highly effective integral attenuator

- Box style construction for the reduction of the airflow velocity

- Electronic control components for different applications (Easy, Compact, Universal, and LABCONTROL)

- Closed blade air leakage to EN 1751, up to class 4

- Casing air leakage to EN 1751, up to class C

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TS for the reduction of air-regenerated noise

- Hot water heat exchanger of Type WT for reheating the airflow

TVA

FOR EXTRACT AIR SYSTEMS WITH DEMANDING ACOUSTIC REQUIREMENTS

VAV terminal units for extract air control in buildings with variable air volume systems and demanding acoustic requirements

- Highly effective integral attenuator

- Box style construction for the reduction of the airflow velocity

- Electronic control components for different applications (Easy, Compact, Universal, and LABCONTROL)

- Closed blade air leakage to EN 1751, up to class 4

- Casing air leakage to EN 1751, up to class C

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TS for the reduction of air-regenerated noise

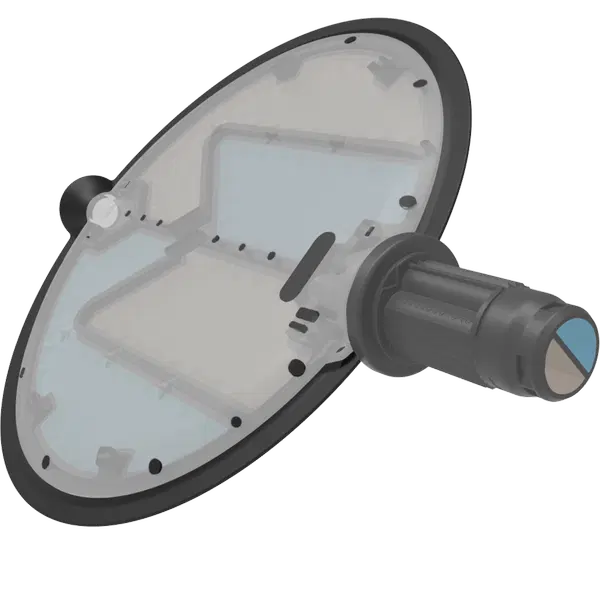

TVRK

FOR CONTAMINATED AIR

Plastic circular VAV terminal units for aggressive extract air in variable air volume systems

- Casing and damper blade made of flame-resistant polypropylene

- Slide-out effective pressuresensor allows for easy cleaning

- Suitable for the control of volume flow rate, room pressure or duct pressure

- Electronic control components for different applications (Universal and LABCONTROL)

- Suitable for airflow velocities up to 13 m/s

- Closed blade air leakage to EN 1751, class 3

- Casing air leakage to EN 1751, class B

Optional equipment and accessories

- With flanges on both ends

- Matching flanges for both ends

- Plastic secondary silencer Type CAK for the reduction of air-regenerated noise

TVM

FOR DUAL DUCT SYSTEMS

VAV dual duct terminal units for dual duct systems with variable volume flows in buildings with demanding acoustic requirements

- Individual temperature control for each room or zone

- Highly effective integral attenuator

- Electronic control components for various applications

- Closed blade air leakage to EN 1751, up to class 4

- Casing leakage to EN 1751, Class B

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TS for the reduction of air-regenerated noise

TVLK

OPTIMISED FOR USE IN LABORATORIES AND ON FUME CUPBOARDS

Plastic circular VAV terminal units for aggressive extract air in laboratories and production facilities

- Casing and damper blade made of flame-resistant polypropylene

- Compact construction, only 400 mm long

- High control accuracy even in case of unfavourable upstream conditions

- Combination with fast-running actuators (air management systems)

- Volume flow rate measurement with bluff body or nozzle

- Slide-out sensor tubes allow for easy cleaning

- Closed blade air leakage to EN 1751, class 4

- Casing air leakage to EN 1751, class C

Optional equipment and accessories

- With flanges on both ends

- Plastic secondary silencer Type CAK for the reduction of air-regenerated noise

TVR-EX

FOR THE CONTROL OF VARIABLE AIR VOLUME FLOWS IN POTENTIALLY EXPLOSIVE ATMOSPHERES (ATEX)

Circular VAV terminal units for variable air volume systems, approved and certified for potentially explosive atmospheres (ATEX)

- ATEX-compliant construction and parts

- Approved for all gases, mists and vapours in zones 1 and 2, with electronic control additionally for dusts in zones 21 and 22

- Suitable for the control of supply or extract air as well as for differential pressure control

- Electronic or pneumatic control components

- Closed blade air leakage to EN 1751, up to class 4

- Casing air leakage to EN 1751, class C

Optional equipment and accessories

- Spring return actuator

- Auxiliary switch with adjustable switching points for capturing the end positions