Control Components

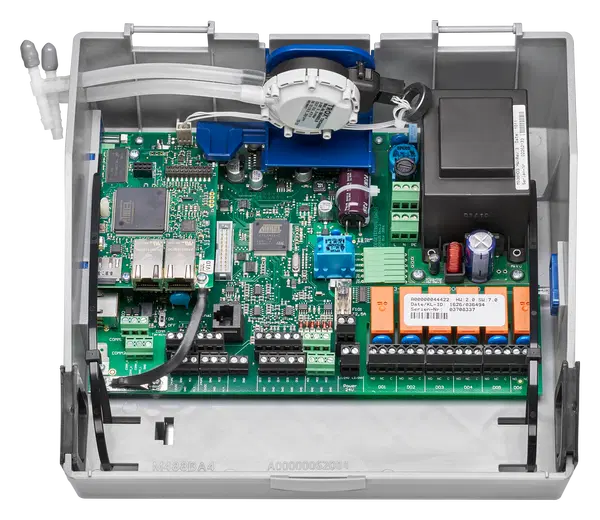

COMPACT, STATIC

WITH SERVICE INTERFACE AND BUS COMMUNICATION FACILITY, FOR CONTAMINATED EXTRACT AIR OR FOR PRESSURE CONTROL

Compact component for VAV terminal units, especially for aggressive air or gases in extract air systems

- Controller, static differential pressure transducer and actuator are fitted together in one casing

- Volume flow rates Vmin and Vmax are factory set as parameters

- Ideal for carrying out service from the switch cabinet or control panel

- Change of parameters using adjustment devices

- Suitable for constant and variable volume flows as well as for Vmin / Vmax switching

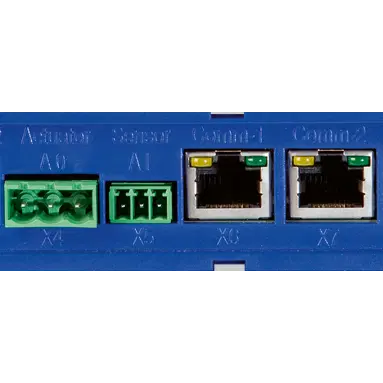

- Bus communication is possible due to the Sauter SLC interface

COMPACT, DYNAMIC

WITH SERVICE INTERFACE AND BUS COMMUNICATION FACILITY

Compact device for use with VAV terminal units

- Controller, differential pressure transducer, and actuator are fitted together in one casing

- Volume flow rates Vmin and Vmax are factory set as parameters

- Ideal for carrying out service from the switch cabinet or control panel

- Change of parameters using adjustment devices

- Suitable for constant and variable volume flows as well as for Vmin / Vmax switching

- Bus communication is possible due to the following interfaces: MP bus, LonWorks, Modbus RTU, KNX

EASY

QUICK AND EASY HANDLING

Control components for VAV terminal units, to be mounted on the terminal unit for easy operation

- Simplified ordering and on-site assignment to rooms as selection is based on the nominal size of the duct

- Rapid volume flow rate setting without additional device

- Indicator light simplifies functional checking

- Proven technology of the Compact volume flow controllers

- Suitable for constant and variable volume flows as well as for Vmin / Vmax switching

UNIVERSAL, STATIC

FOR CONTAMINATED EXTRACT AIR OR FOR PRESSURE CONTROL

Modular control components for VAV terminal units, especially for aggressive media in extract air systems

- Module selection based on application

- Actuators with selected actuator forces

Options

- Actuators with safety function for ‘damper blade OPEN’ and ‘damper blade CLOSED’ (spring return actuators)

RETROFIT

RAPID REPLACEMENT WITHOUT INTERRUPTION OF SYSTEM OPERATION

Control components for VAV terminal units as a replacement for previous types while the VAV terminal unit remains installed

- Easy alternative to replacing a complete unit

- Replacement in case of modernisation

- Extended range of functions

- Installation without interruption of system operation

- For circular ducts of nominal sizes 100 to 400 mm

Retrofit parts kit consists of:

- Control components Easy, Compact or Universal

- Differential pressure sensor

- Accessories

RC

FOR THE INDIVIDUAL TEMPERATURE CONTROL IN ROOMS

Lower operating costs due to intelligent sensor technology

- Temperature range 10 – 45 °C

- For variable air volume systems and 2-pipe or 4-pipe air water systems

- With integral temperature sensor

Optional equipment

- Room occupant can select the operating mode

- Remote control for RC/M1